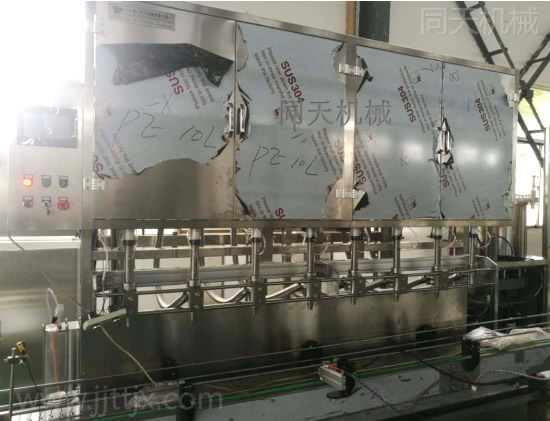

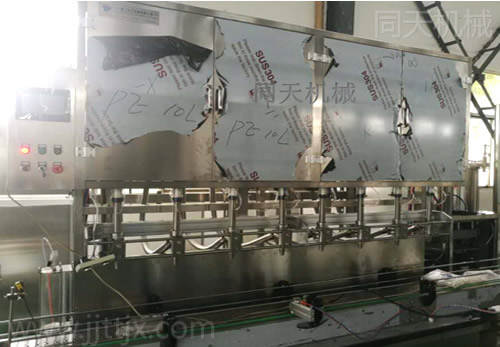

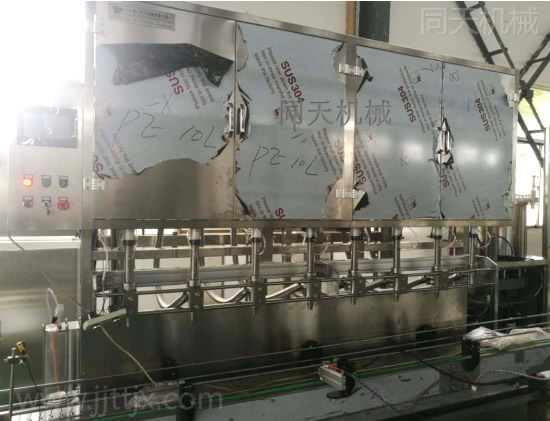

The automatic linear filling machine is mainly suitable for the filling of various viscous, non-sticky, corrosive and non-corrosive liquids. It is suitable for filling in small sizes below 1L, small packages of 1L-5L, and medium packages of 5L-20L. It adopts flowmeter type measurement, accurate measurement, stable work and low failure rate. High and low double-speed filling to avoid overflow. The humanized control system has specific intelligent protection functions, and automatically alarms and displays the cause of the failure in case of failure to ensure safe production.

1. It is convenient to switch and adjust the size of filling bottle.

2. Fully automatic filling, the filling speed is adjustable by frequency conversion, and the filling accuracy does not exceed plus or minus 0.5 parts per thousand.

3. The filling valve does not splash or drip, and has a vacuum suction and anti-drip device;

4. Two-speed filling device;

5. The filling head can be individually shielded, and each filling head can be independently manually controlled and adjusted without affecting the use of other filling heads.

6. The filling tank has automatic level control and oil spill prevention devices to ensure that the oil supply pump can be automatically controlled to work stably; the equipment needs to be equipped with an automatic oil drain function.

7. Equipped with digital display control, according to different product specifications, different filling requirements can be selected on the digital display screen, and the volume of each bottle of filling oil can be monitored and adjusted.

8. The parts of the equipment that are in direct contact with grease are all made of 316 stainless steel, and the outer frame is made of 304 stainless steel.